PV column

Photovoltaic

2022/07/11

Examples of “Repowering” Photovoltaic Power Plants

It has been 10 years since the Feed In Tariff (FIT) for Photovoltaic power plant was introduced in Japan in 2012. With the aging of existing PV plants, product warranty periods for PV inverters and other products, and the emergence of new technologies and products, an increasing number of PV plant owners and O&M companies are considering improving the amount of electricity generated by PV power plants through retrofitting (repowering) at the time of maintenance.

This column, we would like to introduce an overseas case study of repowering of a 2MW solar power plant built in 2011, in which Tigo’s products were installed. (Source: Tigo Energy)

*****

Case Study

Remedying Mismatch & Shading with Tigo’s Monitoring & Optimization Functionalities

“With the Tigo system, our PV production increased by [more than]10%… I now have a prompt and precise strings and modules monitoring solution.” – Commercial PV system Owner

- Location

- Jesolo (VE), Italy

- System size

- 1,980 kWp

- Modules

- UE Solar & CNPV (225W & 235W)

- Inverter

- FRIEM RECon 30H-600

- Installer

- Jessolar S.r.l.

Summary

Connected in March 2011, the Jessolar PV plant is an integrated PV system that is compliant with the second edition of the Italian Feed-In Tariff. It consists of 8,610 solar modules with a total power of 1,980kW.

Over the years, this system revealed a 9% decrease in production. Therefore, the adoption of a monitoring system to identify, contain, and solve the reasons of this efficiency drop became mandatory. After an accurate analysis and the official approval from GSE (Italian National Grid Operator and supervisor of Feed-In Tariff) in 2015, the customer opted for Tigo’s optimizers with monitoring and optimization functionalities.

The Solution

Thanks to Tigo’s monitoring and optimizing functions, the customer observed a clear improvement in mismatch and shading production issues. The customer is now capable of easily finding and solving other problems affecting this plant

– including:

- ten disconnected strings (~200 modules) have been reconnected;

- more than 210 damaged solar modules have been detected (whose production drop fluctuated between 33% and 100%);

- two inverter anomalies have been discovered and since remedied by the manufacturer’s technical service.

Comparing PV production data between H1’2016 and H1’2017, there is a clear 14.2% performance improvement. This result will improve even more once the scheduled substitution of the 210 damaged solar modules is complete (currently, this issue is contained by optimization features).

Customer Experience

“With the Tigo system, our PV production increased by 10% and – above all – I now have a prompt and precise strings and modules monitoring solution.

Furthermore, PV-Safe function – cutting voltage at module level – prevents any fire risk.

Even on-site cleaning operations have been streamlined. Right now, the operator can act in real time, managing any eventual problem or anomaly concerning each module.

In view of a total expense of about 250.000 €, I predict a recovery of approximately 120.000 € by the end of 2017, with a two years ROI. Moreover, Tigo’s monitoring solution offers me more bargaining power with modules/inverters manufacturers.”

–Massimo Gribaldo, Jessolar Srl

*****

The same effect is expected for repowering of low voltage class PV plants, high voltage PV plants with string inverters, and utility scale PV plants with large central inverters, which are common in Japan.

Tigo’s Optimizer TS4-A-O can be attached to the modules of each string of MPPT circuits of the PV inverter, making it possible to improve each string where shading effects or variations in module output are a concern.

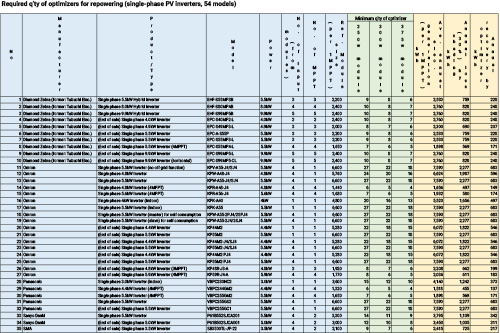

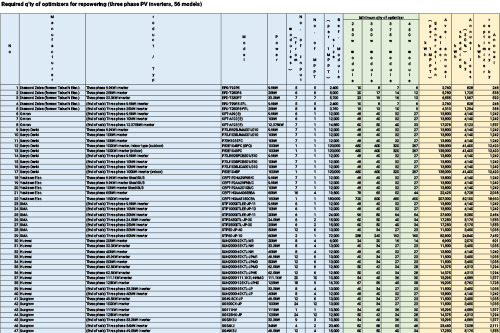

We have created a list of the minimum q’ty of optimizers required for repowering for each of the major PV inverters in the Japanese market. For reference, we have also listed the normal annual power generation (assuming Tokyo) for each MPPT circuit corresponding to the minimum number of units, and the expected recovery power generation (recovery of 30% of the power generation loss) assuming that the relevant string had an annual power loss of 30% due to shading.

Please note that the conditions of the PV plant will make a difference.

We can also support PV inverters not listed in the above list, so please contact us (info@e-solar.co.jp) if you are interested in PV inverters or repowering of your PV plant.

Source: Tigo Energy